Vacuum soldering ovens in automotive production

2024-07-01

Vacuum soldering ovens in automotive production

Before we look at how useful vacuum brazing ovens can be for car, truck, and motorcycle manufacturers, it's best to accurately define the process for those who aren't already experts in the field. Essentially, soldering joins two metals to each other using a metal filler. In order for the connection to be reliable, the melting temperature of the filler must be lower than the liquefaction temperature of either of the two metals being joined. When the filler melts, it must be in physical contact with either side of the joint, forming a strong joint once cured. Obtaining a strong connection: In most cases, this is achieved by the vehicle manufacturer by using the correct type of filler metal for the specific connection. In fact, there are many options, for example, the filler can be in the form of wire, sheet or even paste. It simply depends on the type of application in which the process is being carried out.

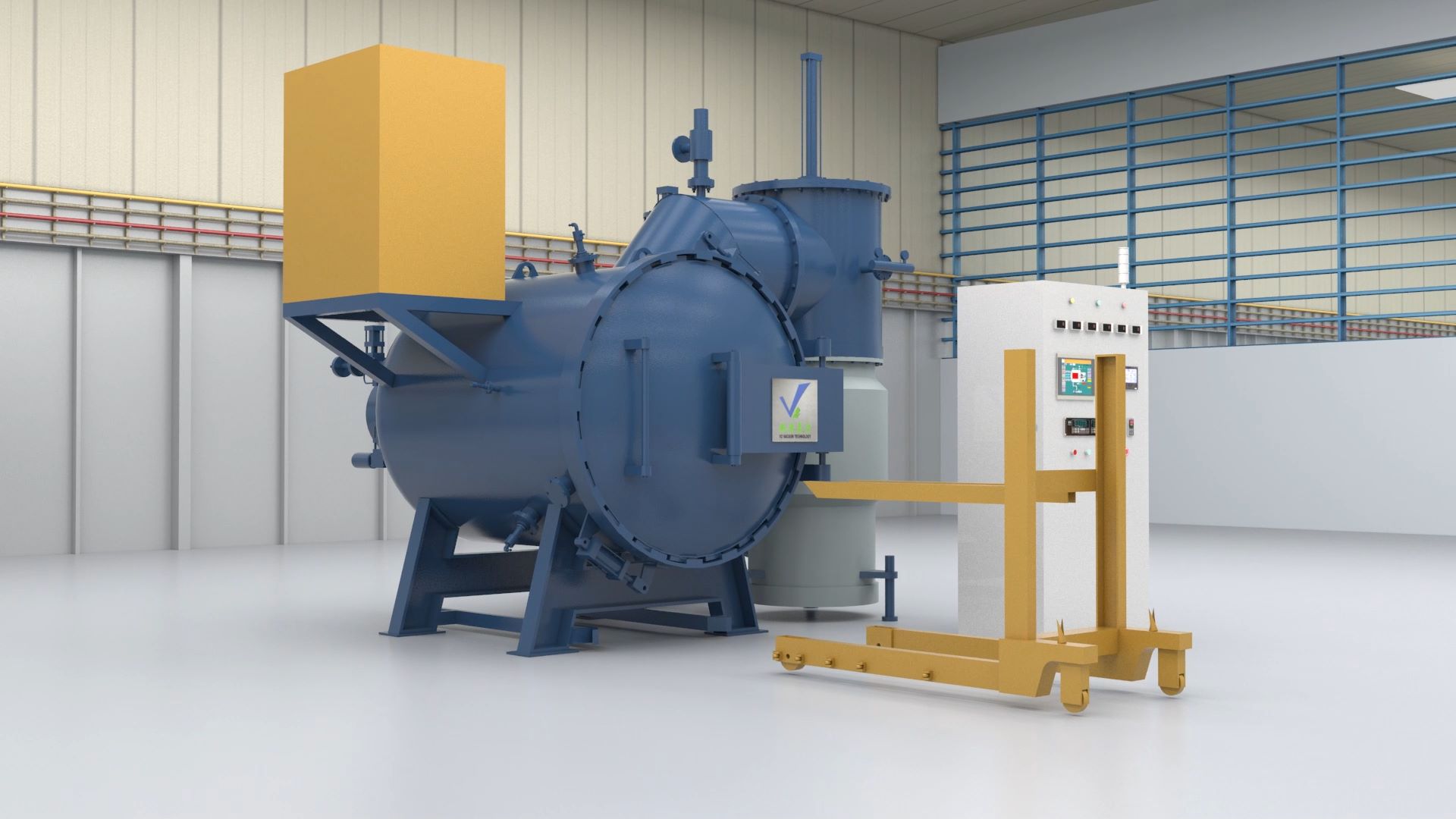

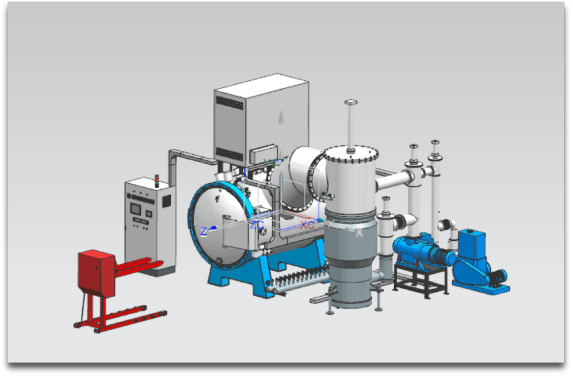

Of course, to obtain a high-quality connection - both in terms of physical resistance to stress and from a corrosion point of view - it is desirable to have a strictly controlled environment. This is because dirt and even air particles can contaminate the soldering process, and leading companies in the automotive industry want to avoid this at all costs. This is where vacuum soldering comes to the rescue, which we will discuss later. Next, you'll also learn how advanced vacuum brazing oven technology ensures that the stringent quality control measures required for all metal joints in the automotive industry are met. Automotive Heat Treating and Vacuum Furnace Technology: Effective brazing heat treatment requires the cleanest atmosphere possible, and for precision engineering applications such as the automotive industry, this means creating a vacuum. Since the vacuum furnace reduces any contamination by impurities in the environment to almost zero, the joined metals will have high mechanical strength and durability.

This is especially important for car manufacturers because complex parts must be connected to each other and often have non-standard shapes. Vacuum oven brazing also makes sense because the automotive industry also involves a large number of connections in a relatively small space. For this reason, this heat treatment is commonly used in areas such as water heat exchanger connections. In the automotive industry, the use of aluminum as the core element of premium heat exchangers is becoming increasingly popular. For example, AA 3xxx and 4xxx aluminum alloys are widely used in this sector. The main reason these special alloys are so useful is that they have a very low specific gravity and yet have a high level of thermal conductivity. As mentioned above, one of the cleanest environments for precision soldering in the automotive industry is vacuum. Therefore, readers interested in the heat treatment of automobiles and aluminum alloys should take a closer look at the individual characteristics of semi-automatic vacuum brazing ovens that make them ideal for common applications required in the automotive industry.