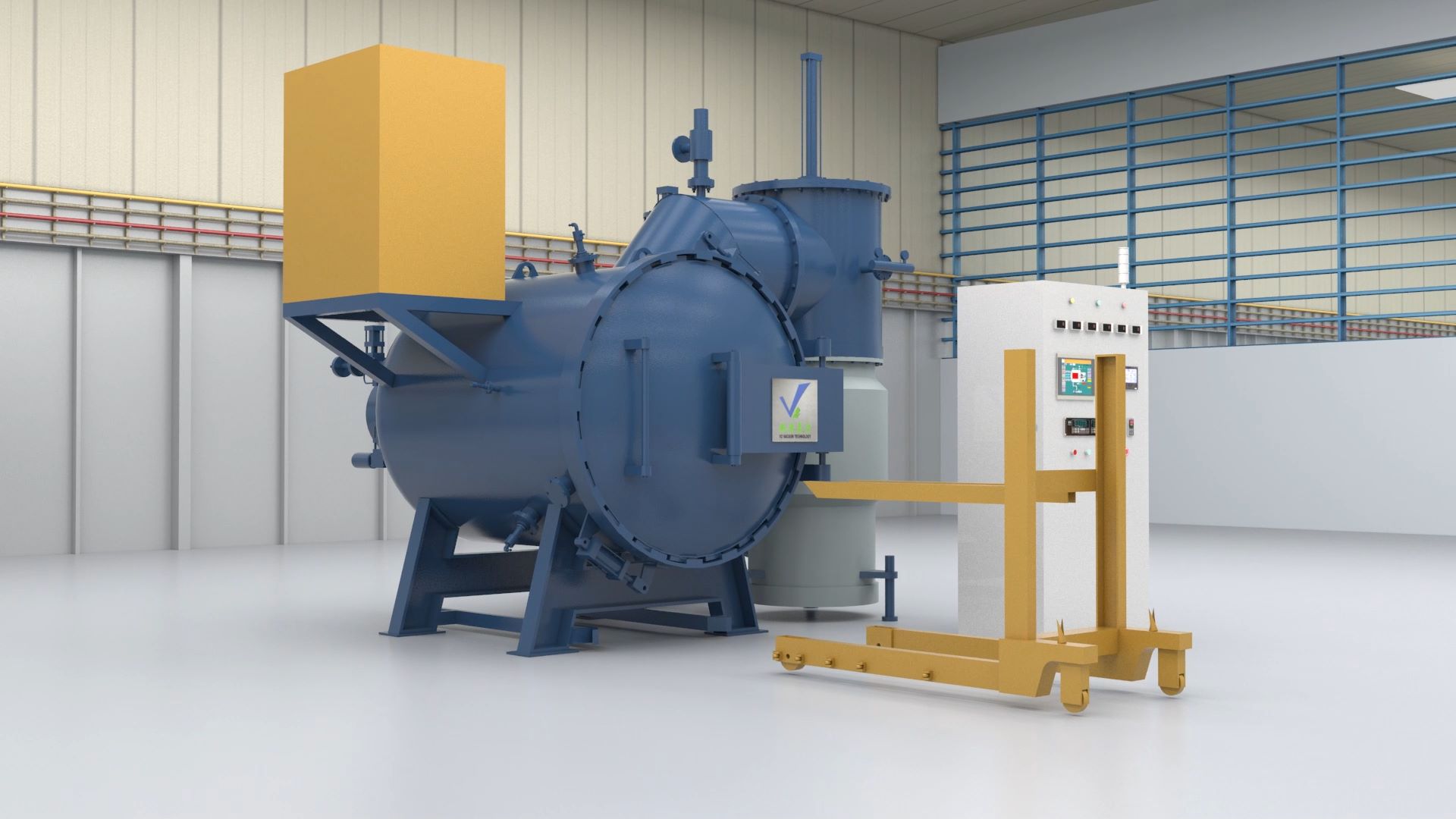

Vacuum furnaces for heat treatment in the aerospace industry

2024-07-01

Vacuum Heat Treatment Furnaces for the Aerospace Industry

Vacuum heat treatment furnaces have a wide range of applications. However, one of the most important areas is the heat treatment of aluminum alloys used in aircraft construction. While the type of alloy chosen by the aircraft designer is important, the heat treatment of that metal also plays a critical role in the aircraft's design. For obvious reasons, aircraft must operate at optimal levels, and environmental conditions are closely related to the strength and service life of the aircraft. The service life of an aircraft depends on the grain structure of its alloys, which in turn is entirely dependent on vacuum heat treatment.

Vacuum furnaces are used for heat treatment.

Vacuum heat treating furnaces improve the overall condition of metal alloys because they cover the area more evenly, allow for faster cooling and improve

overall service life and functionality of the alloy.

NASA has defined nine types of vacuum heat treatment for the purposes of training and certification of its vacuum heat treatment technicians.

Age hardening

It is a heat treating process that involves applying low temperature long enough to harden the alloy to the required temperature.

Artificial aging

At this stage, the alloy is processed at temperatures above room temperature.

Eutectic melting

This is the local melting of low melting point eutectic components in some alloys. This type of melting usually results in significantly less ductility and reduced resistance to fatigue cracking

Natural aging

This is normal aging of metals at room temperature.

Hardening from precipitation

This is age hardening caused by the formation of sediment. Hardening

This is the rapid cooling of iron.

Solid solution heat treatment

It is a heat treatment in which at least one of the phases goes into solid solution and is maintained in solid solution by rapid cooling.

Relieving tension

This is usually a thermal cycle to relieve pressure over time.

Vacation

This is a thermal cycle performed after hardening to improve the strength or other mechanical properties of the metal. So let's answer the question, why are vacuum heat treatment furnaces important for the aerospace industry? This type of heat treatment of alloys is important because it allows designers to build aircraft from stronger materials, resulting in improved performance, fewer repairs, and longer overall service life.