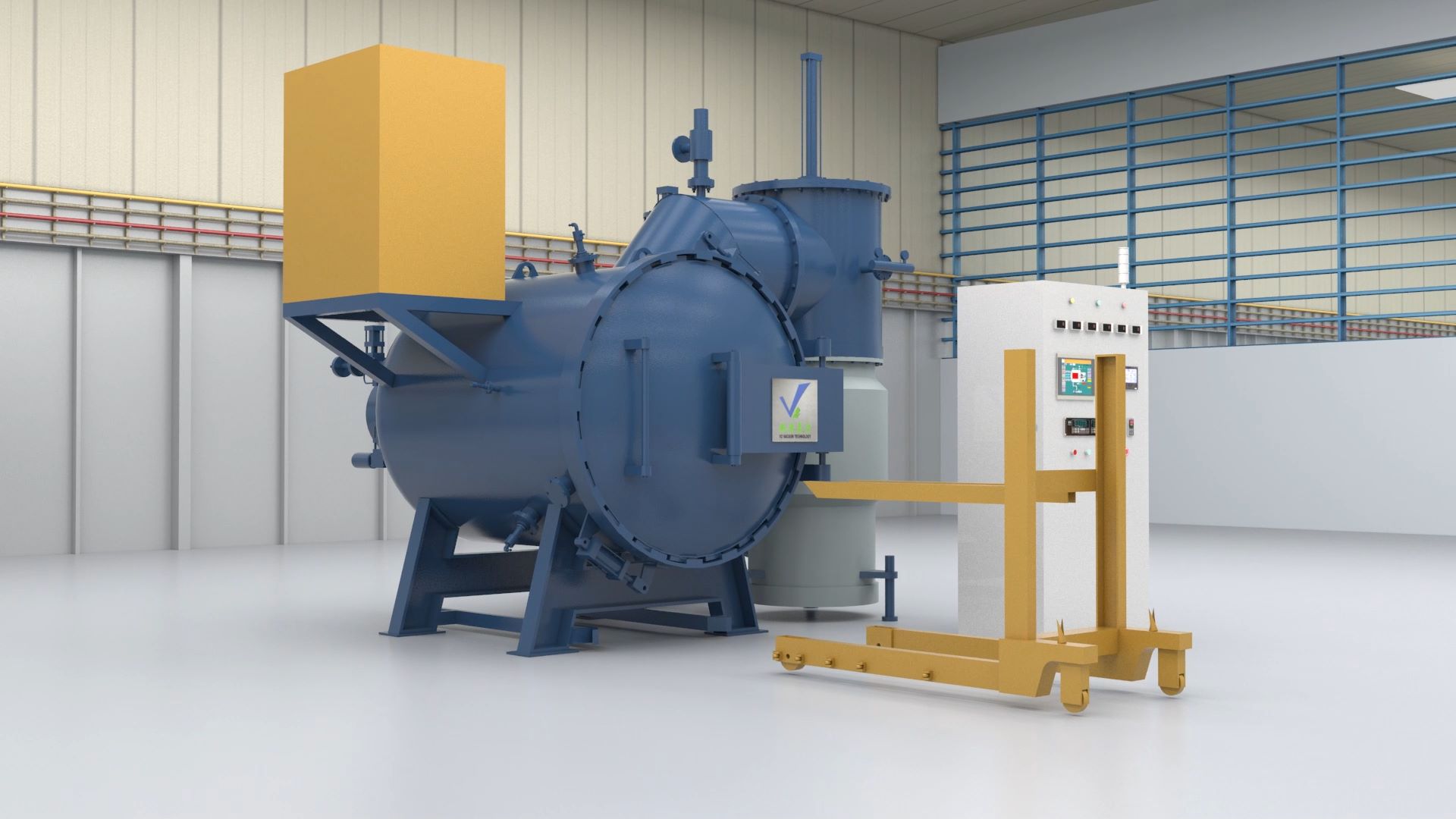

high quality ceramic sintering vacuum furnaces

2024-07-02

Vacuum furnaces for sintering high-quality ceramics

1.Usage

Vacuum hot pressing furnace is mainly used for high temperature sintering and hot pressing of powder ceramic capital and powder sintered materials in vacuum (or protective atmosphere), and high temperature sintering and hot pressing of other metal or non-metallic materials in vacuum (or protective atmosphere).

Combining vacuum hot pressing and high temperature sintering together, it is mainly used in powder metallurgy, ceramics industry, and is suitable for the forming and sintering process in a special atmosphere such as oxygen enriched.

2.Structure of vacuum hot pressing furnace

2.1 Oven parts

2.1.1 The furnace body is a vertical casing, the inner (304 stainless steel), outer drum and flange are made of high quality carbon steel. The inner and outer barrels are welded to the upper and lower flanges to form a single unit. A jacket is formed between the two layers, which is cooled by water and removes the heat transferred to the inner wall of the furnace body. In the center of the furnace body there are holes for air exhaust, holes for measuring temperature with a thermocouple and inspection holes.

2.1.2 The upper part of the furnace body is the furnace cover, the furnace cover is welded from inner (304 stainless steel) outer head and flange (high quality carbon steel material), and cooled by water in the middle; The opening of the furnace lid is mechanical and manual, the top of the lid is lifted and panned to open the furnace, and the furnace is equipped with a pressure head (upper pressure head), pressure sensor and pressure device, and the day is equipped with a ventilation door; respectively using upper and lower pressure heads (304 stainless steel). Steel) from materials with circulating cooling water. The furnace body in the middle of the infrared thermometer temperature measurement hole and inspection holes are equipped with inflatable holes to avoid the inspection hole glass being contaminated by pollutants in the furnace.

2.1.3. The bottom of the vacuum hot pressing furnace is also composed of an inner (304 stainless steel) outer cover and a flange (high quality carbon steel material). The middle part is cooled with water and fixed in the lower part of the furnace body. The bottom of the furnace is equipped with an electrode input device, an air supply valve, a low pressure head and a sensor indicating the moving distance. The pressure head is made of stainless steel and equipped with circulating cooling water.

2.1.4. The heating element is made of graphite rods. The heated graphite rods are processed into a three-phase heating element and connected to the electrodes. After the step-down transformer, the three-phase power supply of the electric furnace control system is connected to the two leading electrodes through copper plates, forming a control loop. The electrode block has a water cooling cycle, which

2.1.5. The heat shield around and on top of the furnace roof is made of multi-layer graphite felt and 304 stainless steel supports. The heat shield at the bottom of the hot press vacuum furnace is made of graphite and is easy to install and maintain. The heat shield at the bottom of the furnace is made of graphite and equipped with several graphite heads made of high-strength graphite, which can be used to adjust the height of the molds during the pressing process.

2.2 Hydraulic system

2.2.1 The hydraulic system consists of an electric hydraulic unit, a bypass valve, an electromagnetic reversing valve, a hydraulic cylinder and a fixed frame. The hydraulic cylinder is installed in the middle of the bottom of the vacuum hot pressing furnace. Hydraulic oil through the electric hydraulic system into the hydraulic cylinder, through the relief valve and the logistics electromagnetic reversing valve into the hydraulic cylinder, so that the hydraulic cylinder is up and down. It can realize the function of regulating and holding pressure. According to the user's technical requirements, the automatic pressure control function can be realized by installing an intelligent software instrument with digital display. Pressure and displacement are shown on a digital display.

2.2.2 The stationary frame consists of a beam, a base, a long column and a furnace frame.

2.3 Vacuum system

2X-70 mechanical pump + ZJP300 Roots pump + KT300 diffusion pump + vacuum tube + vacuum pneumatic rotary valve and bellows vacuum gauge kit

2.4 Electrical control

2.4.1 A low-voltage transformer and a thyristor regulator are used as a power source. The three-phase voltage of 380 V passes through a step-down transformer, the voltage is reduced to 30 V and is supplied through cables to the electrodes. The system has soft start, soft shutdown, constant current and overcurrent protection.

2.4.2 Temperature control is carried out using a digital temperature programming controller based on the process curve specified by the user. With PID self-tuning function, it can also control the temperature manually according to the user's needs.

2.4.3 The whole furnace has the function of automatic water pressure lock, overheat and overcurrent, alarm, protection and main power shutdown in working condition. Sound and light indication of alarm status.

2.5 Water cooling system of vacuum hot pressing furnace

The cooling water comes from the main pipe and through each pipe goes to the furnace shell, furnace cover, furnace bottom, electrode, upper and lower discharge pipe, diffusion pump, mechanical pump and other places that need to be cooled. It is then collected and dumped into a water tank. Each cooling water has a manual valve that allows you to adjust the flow as needed. The inlet pipeline is equipped with an electrical contact pressure gauge. When the water pressure drops below the set value, the control system gives a sound and light signal and automatically turns off the power to the water heater. When inlet pressure: >1.5 kK, inlet diameter: 2.5 inch, outlet diameter: 2.5 inch, a cooler is required, which is an additional cost.