Products

-

Vacuum furnace for laboratory sintering

-

Double Chamber Vacuum Furnace for Oil and Gas Quenching

-

High Temperature Vacuum Atmospheric Sintering Furnace

-

Inclined Rotating Vacuum Tube Sintering Furnace

-

Vacuum Tempering Furnace for Heat Treatment

-

Furnace for vacuum soldering of aluminum radiators

-

High Temperature Vacuum Soldering Furnace for Brazing Copper Alloys, Stainless Steel

-

Vacuum Annealing Furnace Heat Treatment

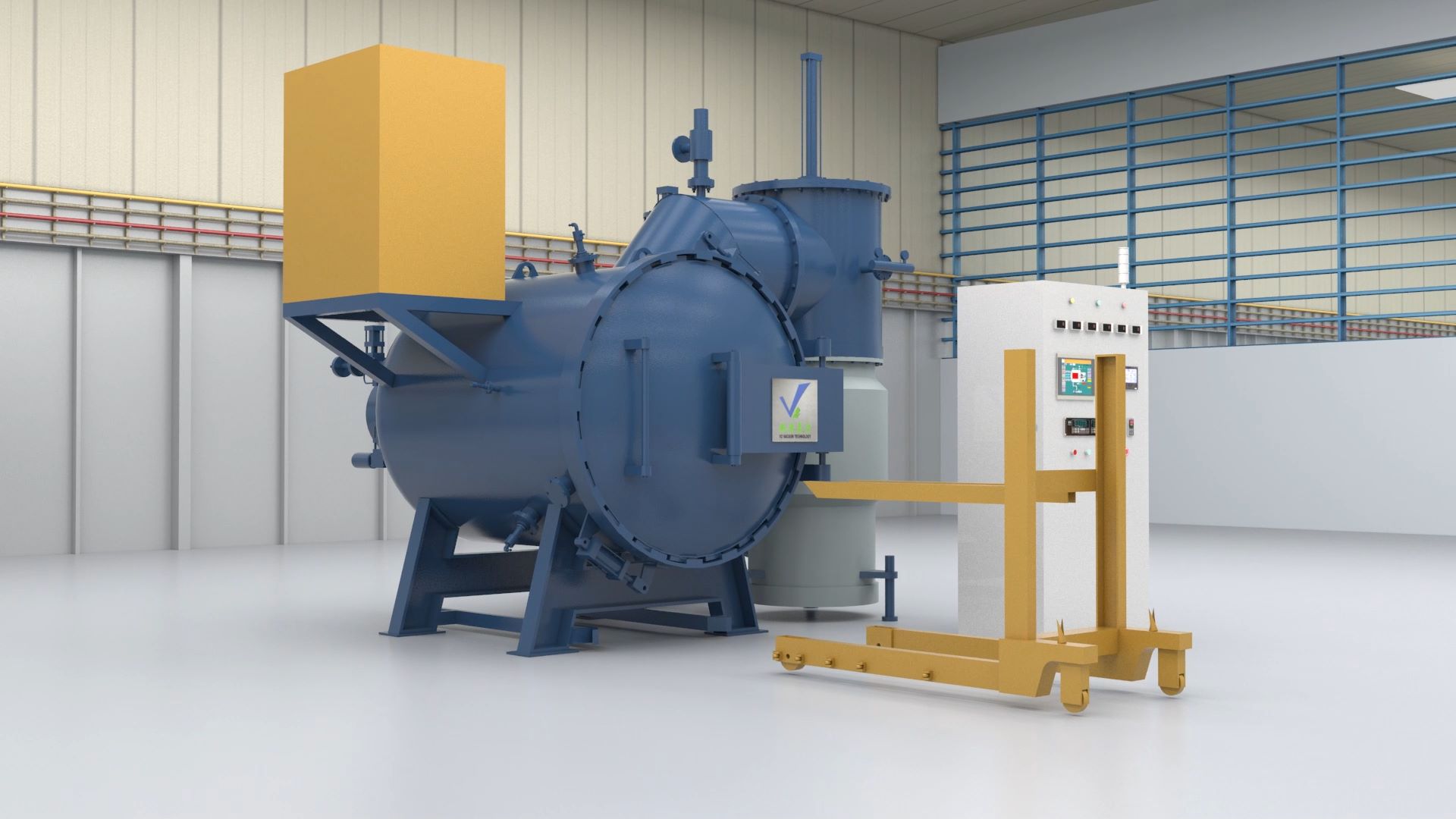

Vacuum Gas Quenching Furnace for Heat Treatment

High pressure vacuum air quenching furnace is mainly used for cold and hot work of mold steel, high-speed steel, die steel, stainless steel, alloy steel, titanium alloy and other materials, vacuum bright air quenching, can also be used for titanium alloy vacuum dehydrogenation, vacuum soldering and so on.

Convenient operation, manual/automatic free switching, can achieve fully automatic control, completely avoid human error in the working process.

With a perfect alarm system, it can effectively ensure the protection of equipment.

The gas extinguishing pressure can be adjusted to suit different materials, saving costs.

Description

marker

use:

Vacuum Gas Quenching Furnace for Heat Treatment

Specification

| model | size (mm) | Load capacity (Kg) | Heating element | Heating power (kw) | Maximum temperature (℃) | Temperature Uniformity (±℃) | Maximum vacuum (Pa) | Cooling pressure gas (Bar) |

| VTG-335 | 300×300×500 | 100 | Mo/Graphite | 80 | 1300 | 5 | 6×10-3 | 6/10 |

| VTG-446 | 400×400×600 | 200 | Mo/Graphite | 100 | 1300 | 5 | 6×10-3 | 6/10 |

| VTG-557 | 500×500×700 | 300 | Mo/Graphite | 120 | 1300 | 5 | 6×10-3 | 6/10 |

| VTG-669 | 600×600×900 | 500 | Mo/Graphite | 150 | 1300 | 5 | 6×10-3 | 6/10 |

| VTG-8812 | 800×800×1200 | 1000 | Mo/Graphite | 240 | 1300 | 5 | 6×10-3 | 10 |

| VTG-9920 | 900×900×2000 | 1500 | Mo/Graphite | 350 | 1300 | 5 | 6×10-3 | 10 |

vacuum gas quenching furnace for heat treatment

For many years, high-pressure vacuum gas quenching furnaces have been the process of choice for heat treating high-speed steels as well as hot- and cold-worked tool steels. With the development of self-contained vacuum chambers for high-pressure gas quenching, it is often possible to replace oil quenching with quenching in high-pressure vacuum furnaces using nitrogen or helium for heat treating hardened steels or other low-alloy materials. The success of this dry hardening technology is based on its environmental and commercial effectiveness. Quenching gases such as nitrogen or ammonia are completely inert and do not pose an environmental risk. They do not leave any marks on the workpiece or in the hardening furnace.

Advantages of gas hardening

In vacuum furnaces equipped with quenching chambers, quenching gas streams are supplied at a rate that requires the use of high pressure nitrogen or ammonia gas streams. There is a big advantage here: the cooling gas does not cause metal deformation or change in size. This, by the way, is a feature that cannot be replicated when quenching in liquid. In addition, the process is significantly accelerated, so the hardened workpieces receive a more sensitive cooling profile. High pressure gas cooling systems with perfectly timed quench slots are much easier to control than oil or water quench systems.

vacuum furnace Technical features.

1.Horizontal two-chamber oven with horizontal loading design. The type of oven door opening can be customized.

2.Gas quenching chamber with gas circulation from bottom to top or from left to right, high heat transfer rate.

3.HIP chamber is closed before gas quenching, which saves energy.

4.Users can choose the configuration of high power axial fan for gas quenching or high power centrifugal fan for gas quenching according to the processing conditions.