Products

-

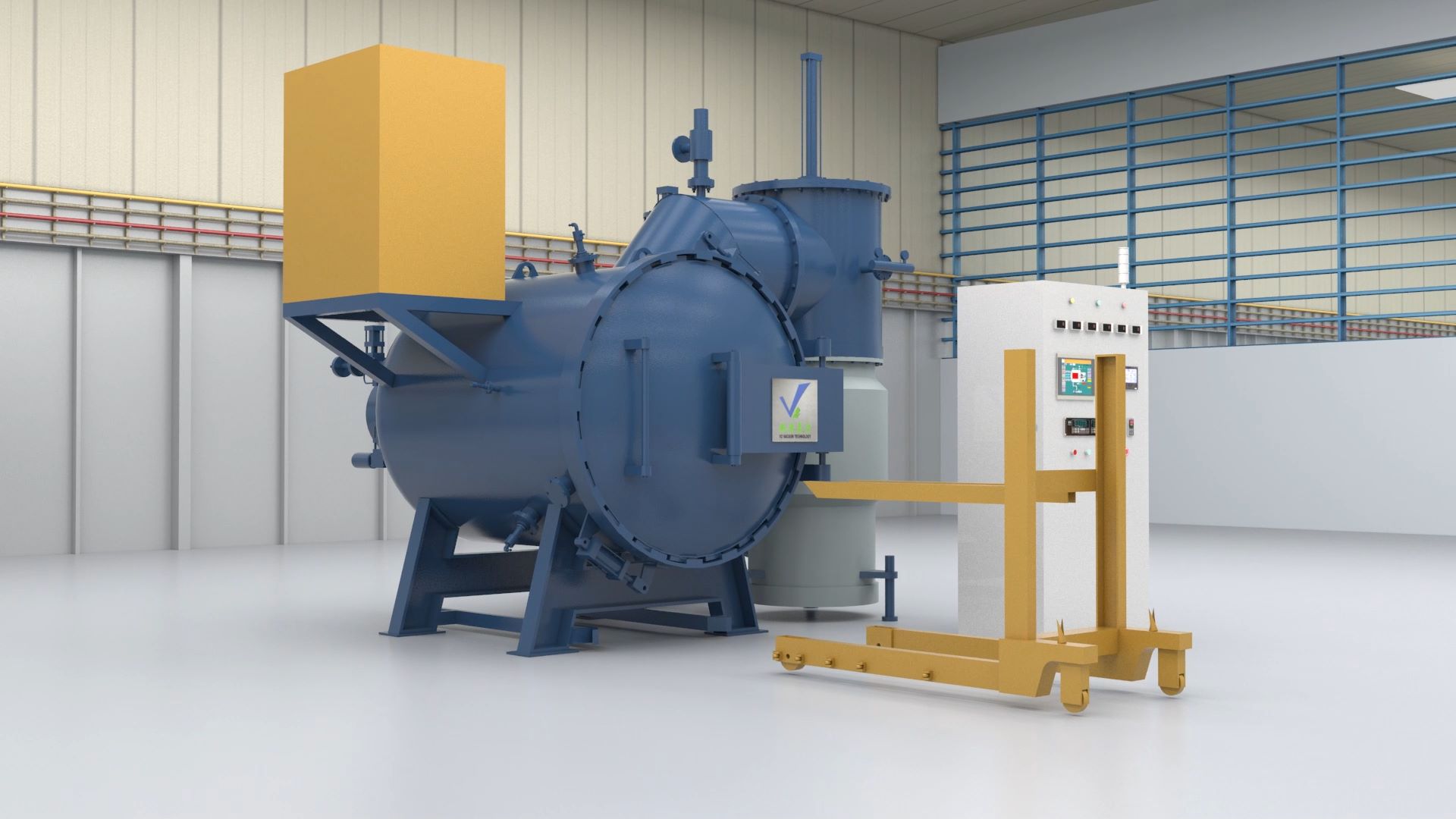

High Temperature Vacuum Soldering Furnace for Brazing Copper Alloys, Stainless Steel

-

Double Chamber Vacuum Furnace for Oil and Gas Quenching

-

Vacuum Tempering Furnace for Heat Treatment

-

Vacuum Annealing Furnace Heat Treatment

-

Furnace for vacuum soldering of aluminum radiators

-

High Temperature Vacuum Atmospheric Sintering Furnace

-

Vacuum Gas Quenching Furnace for Heat Treatment

-

Inclined Rotating Vacuum Tube Sintering Furnace

Vacuum furnace for laboratory sintering

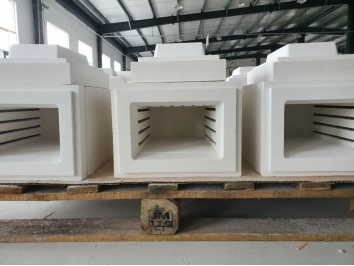

Vacuum atmospheric furnace, this equipment is specially designed for heat treatment of materials under the protection of inert gas, the maximum operating temperature is 1650 degrees, the furnace cavity material is made of high-purity alumina fiber, the surface is coated with high-temperature alumina coating, improving heating efficiency, increasing temperature uniformity while extending the service life furnace service. It is ideal for laboratory and small-scale production.

Description

marker

use:

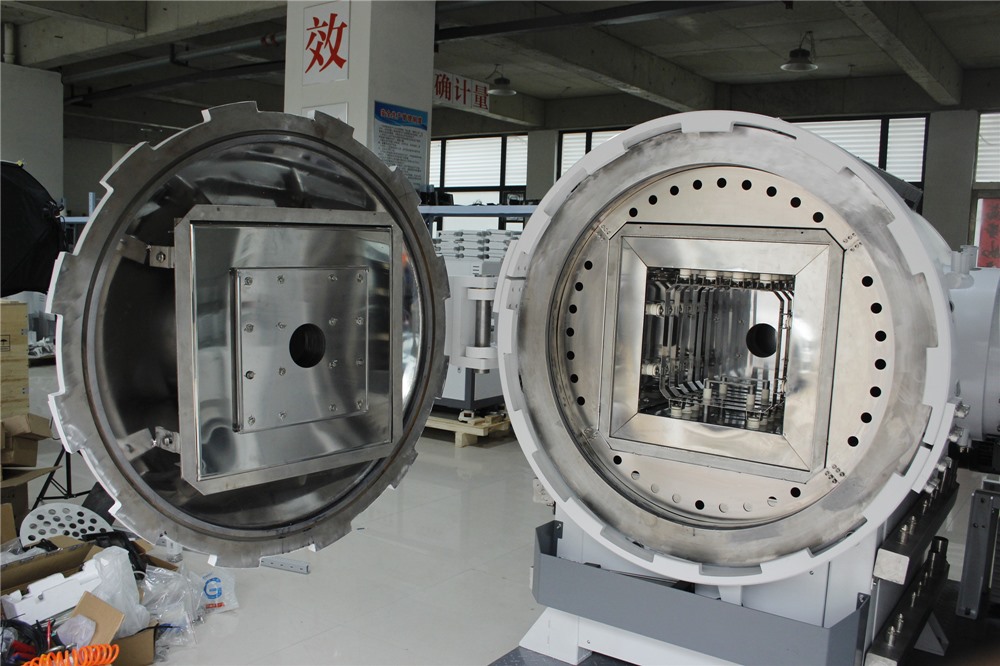

Vacuum furnace for laboratory sintering

The vacuum sintering furnace controls the combustion cycle, and the atmospheric conditions can be changed during operation: from oxidation (eg air to inert gas) or from argon/nitrogen to rough vacuum.

This type of oven allows the process to be carried out in several atmospheres in one cycle: the glue burns in air, and the parts are sintered in a vacuum or inert gas environment.

These furnaces are designed for precise air/inert gas flow control, precise temperature control and excellent temperature uniformity, long-lasting performance and safe operation.

Specification

| model | size (mm) | voltage | Heating element | Maximum temperature (℃) | Temperature Uniformity (±℃) | Mechanical pump (Pa) | Maximum pressure (MPa) |

| VTSL-100 | 100×100×100 | AC:220/380; 50/60Hz | Fe-Cr-Al Alloy/Sic/Mosi2 | 1200/1350/1650 | 1 | 10/20 | 0.5MPa |

| VTSL-150 | 150×150×150 | ||||||

| VTSL-200 | 200×200×200 | ||||||

| VTSL-322 | 300×200×200 | ||||||

| VTSL-433 | 400×300×300 | ||||||

| VTSL-450 | 450×450×450 | ||||||

| VTSL-610 | 610×610×610 |

Other specifications can be customized

Peculiarity

Maximum operating temperature: 1650°C in vacuum, inert atmosphere and air.

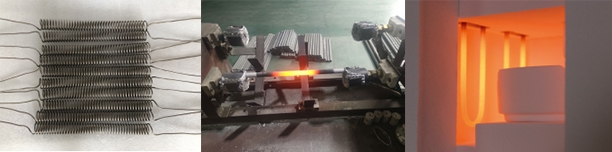

Different heating elements are used for different temperature requirements. Ferrochrome-aluminium, silicon-carbon rod and silicon-molybdenum rod heating elements can be used, which can reach heating temperatures of 1200s/1350s/1650s respectively. And the special heating elements we use are characterized by longer service life, better thermal radiation performance at high temperatures and simplicity replacements.

All types of ovens use energy-saving thermal insulation materials made from polycrystalline aluminum oxide fiber and ceramic fiber to ensure energy efficiency.

Long life thermocouples type K, S, B

The double shell design is equipped with an air cooling system, and the shell surface temperature is less than 60℃.

Excellent temperature measurement accuracy and uniformity

Automatically disable security feature

Custom sizes available upon request

Henan synthe can provide design and production according to your specific needs. If you are looking for a custom heat treatment solution for your company, please contact us.