Products

-

Furnace for vacuum soldering of aluminum radiators

-

Vacuum furnace for laboratory sintering

-

Double Chamber Vacuum Furnace for Oil and Gas Quenching

-

High Temperature Vacuum Atmospheric Sintering Furnace

-

Inclined Rotating Vacuum Tube Sintering Furnace

-

Vacuum Gas Quenching Furnace for Heat Treatment

-

Vacuum Annealing Furnace Heat Treatment

-

High Temperature Vacuum Soldering Furnace for Brazing Copper Alloys, Stainless Steel

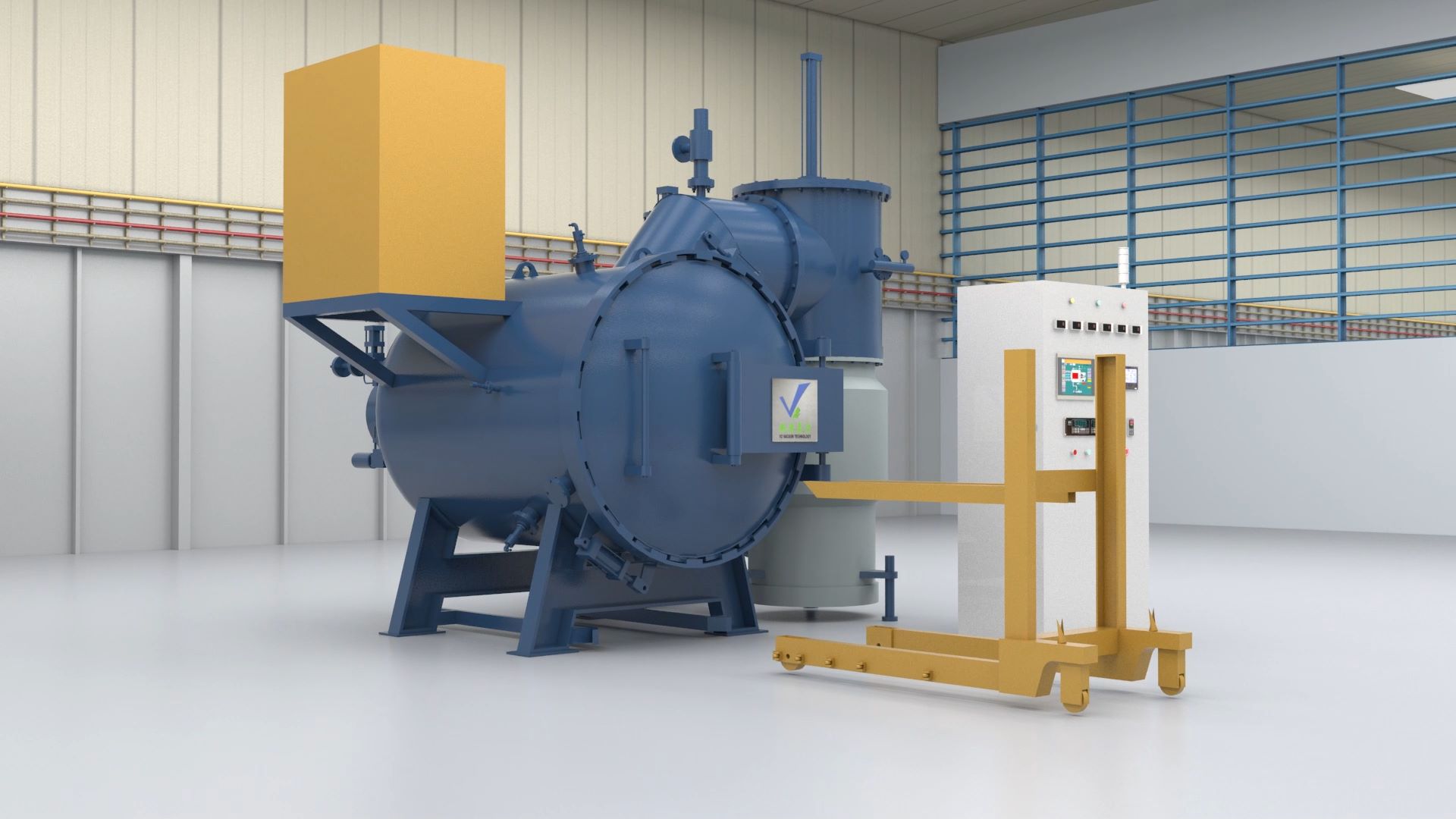

Vacuum Tempering Furnace for Heat Treatment

Vacuum tempering furnace is suitable for quenching and tempering the heat treatment process of metal materials after filling all kinds of material parts with inert gas or weak reducing gas under vacuum. High vacuum tempering furnace is mainly used for tool steel, mold steel, high-speed steel, ultra-high-strength steel, titanium alloy and other materials vacuum hardening vacuum tempering, solution processing after vacuum tempering, recrystallization annealing and non-ferrous metals vacuum bright tempering.

Description

marker

use:

Vacuum Tempering Furnace for Heat Treatment

Specification

| model | size (mm) | Load capacity (Kg) | Heating element | Heating power (kw) | Maximum temperature (℃) | Temperature Uniformity (±℃) | Maximum vacuum (Pa) | Boost speed (Pa/h) | atmospheric pressure (Bar) |

| VTH-335 | 300×300×500 | 100 | Ni-Cr | 30 | 700 | 5 | 4×10-3 | 0.5 | 2 |

| VTH-446 | 400×400×600 | 200 | 50 | ||||||

| VTH-557 | 500×500×700 | 300 | 60 | ||||||

| VTH-669 | 600×600×900 | 500 | 90 | ||||||

| VTH-8812 | 800×800×1200 | 800 | 150 |

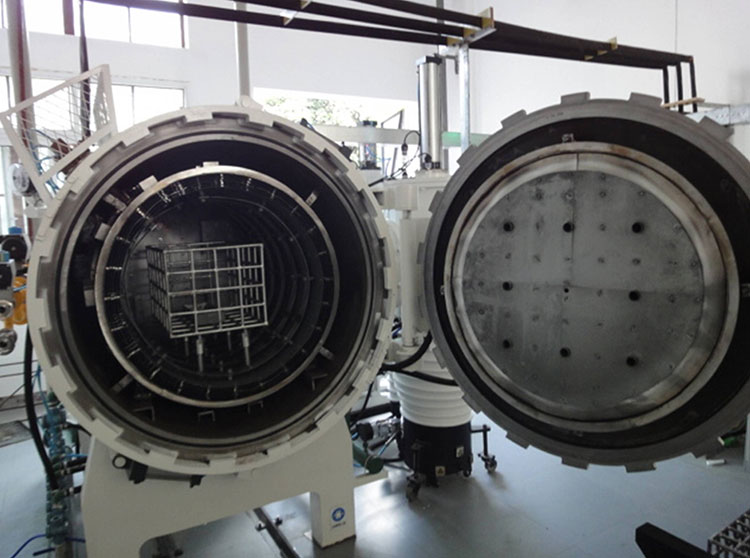

Vacuum tempering furnace

1. Equipped with fast cooling system, high efficiency.

2. The control system uses PLC, and the temperature is controlled by an intelligent thermostat with precise control. 3. high degree of automation. Users can choose automatic or manual switching without disrupting operation.

4. Abnormal status alarm function, easy to operate.

5. Improved environmental protection, saving maintenance costs, saving energy costs.

6. For some vacuum quenching furnaces, the processing process requires low heating temperature, the characteristics of the furnace loaded with a large amount of convective heating can be considered. To achieve in the tempering process, fast heating speed, good temperature demand effect.

7. For some tubular, thin parts, thin-walled annealing process parts, it is recommended to choose top loading or bottom loading vertical structure, which can effectively solve the deformation problem.

What is vacuum holiday?

Vacuum tempering is a specialized heat treatment process used primarily for high speed and alloy steels. The process involves reheating the material to a specific temperature and then cooling it under controlled conditions in a vacuum. The main tool for this process is the vacuum tempering furnace, which provides precise temperature control and uniform processing of the material.

Advantages and role of vacuum tempering

1.Reduced stress after quenching

2.Reduce brittleness caused by quenching/tempering only

3.Increasing the viscosity of the material

4.Precise hardness control