Products

-

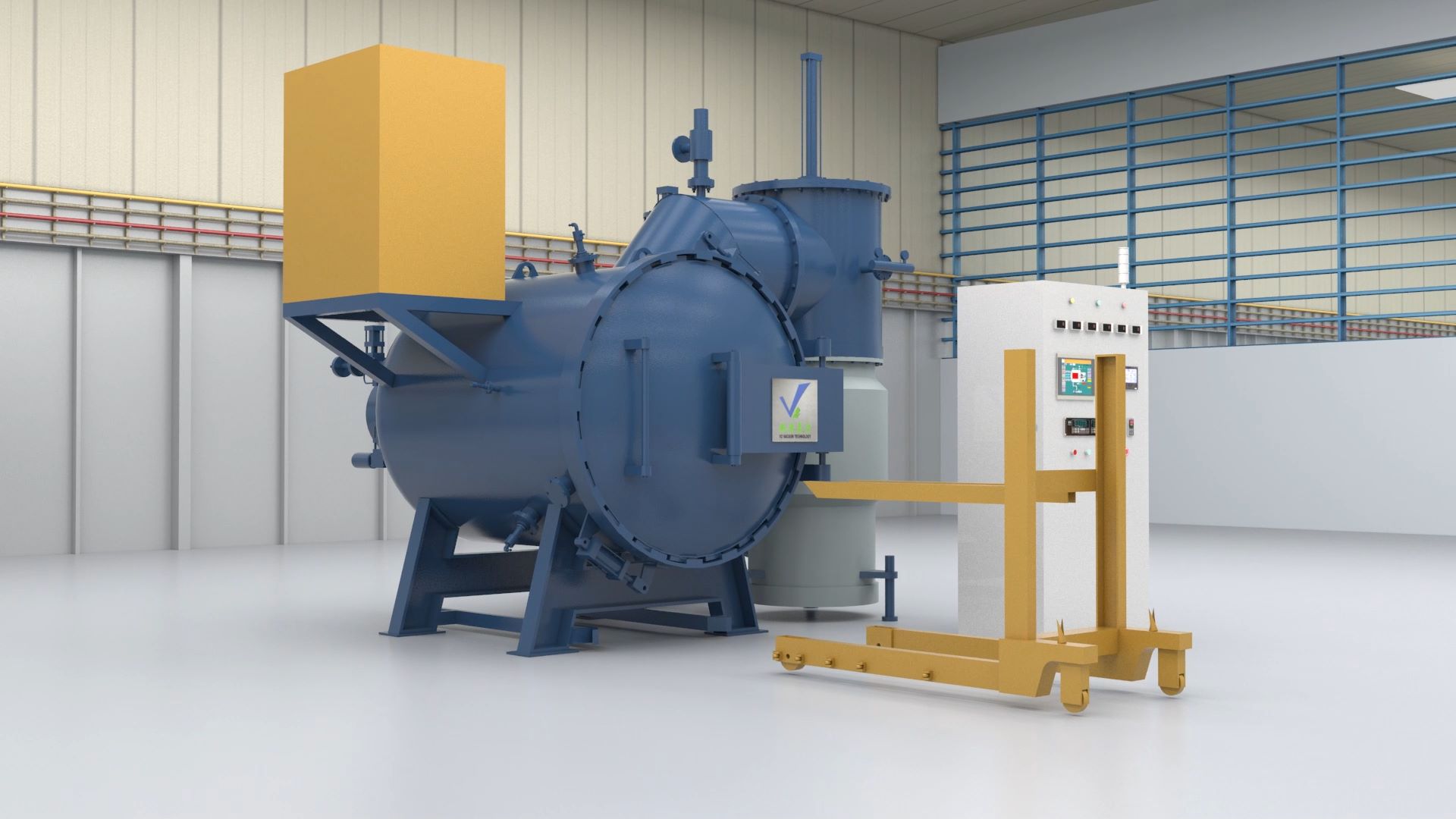

Vacuum furnace for laboratory sintering

-

High Temperature Vacuum Atmospheric Sintering Furnace

-

Vacuum Gas Quenching Furnace for Heat Treatment

-

Vacuum Tempering Furnace for Heat Treatment

-

Vacuum Annealing Furnace Heat Treatment

-

Double Chamber Vacuum Furnace for Oil and Gas Quenching

-

Furnace for vacuum soldering of aluminum radiators

-

High Temperature Vacuum Soldering Furnace for Brazing Copper Alloys, Stainless Steel

Inclined Rotating Vacuum Tube Sintering Furnace

The high temperature rotary vacuum tube furnace can reach a maximum temperature of 1600c. The feature of this equipment is that the furnace tube can rotate when sintering samples, so that the sintered powder samples can be heated better and the temperature uniformity is better. Can be configured to add vacuum or atmosphere, and can add automatic tilting and compaction function, etc., to better meet customer's practical applications, is an ideal choice for heat treatment in laboratory, research institutions.

Description

marker

use:

Inclined Rotating Vacuum Tube Sintering Furnace

Specification

| Heating zone | Heating element | Maximum temperature (℃) | Chimney pipe material | Pipe speed (r/min) | Tilt angle (°) | Temperature Uniformity (±℃) |

| 1-6 or by individual order | Fe-Cr-Al Alloy/Sic/Mosi2 | 1200/1350/1600 | Quartz/stainless steel/corundum/silicon carbide tube optional | 0-30 | ≤45 | 1 |

Other specifications can be customized

Pipe size selection:

Pipe diameter: 50mm, 60mm, 80mm, 100mm, 150mm, 200mm, 250mm or other

hot zone:

Heating zone length: 440 mm, 900 mm or other

Number of heating zones: 1-6 zones are optional

Tube material:

quartz/stainless steel/corundum ceramic/silicon carbide tube optional

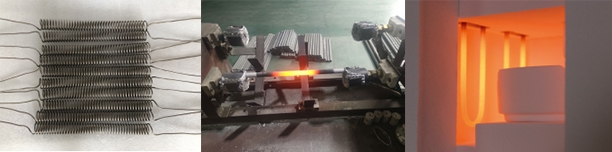

vacuum oven Feature

Different heating elements are used for different temperature requirements. Ferrochrome-aluminum, silicon-carbon rod and silicon-molybdenum rod heating elements can be used, which can reach the heating temperature of 1200℃/1350℃/1600℃ respectively. And the special heating elements we use feature longer service life, better thermal radiation performance at high temperatures and ease of replacement.

High quality ceramic fiber stoves can have better operating insulation and heat insulation, and high energy saving.

Rotary Tube Kiln It can be equipped with feeding hoppers of various sizes to ensure continuous feeding over a long period of time, and the kiln body can be tilted to ensure rapid unloading.

Optional 30-segment or 51-segment PID programmable temperature controller for ease of use with ±1℃ accuracy.

Long life thermocouples type K, S, B

All electronic components come with a one-year limited warranty.

Henan synthe can provide design and production according to your specific needs. If you are looking for a custom heat treatment solution for your company, please contact us.