Products

-

Inclined Rotating Vacuum Tube Sintering Furnace

-

High Temperature Vacuum Atmospheric Sintering Furnace

-

Vacuum furnace for laboratory sintering

-

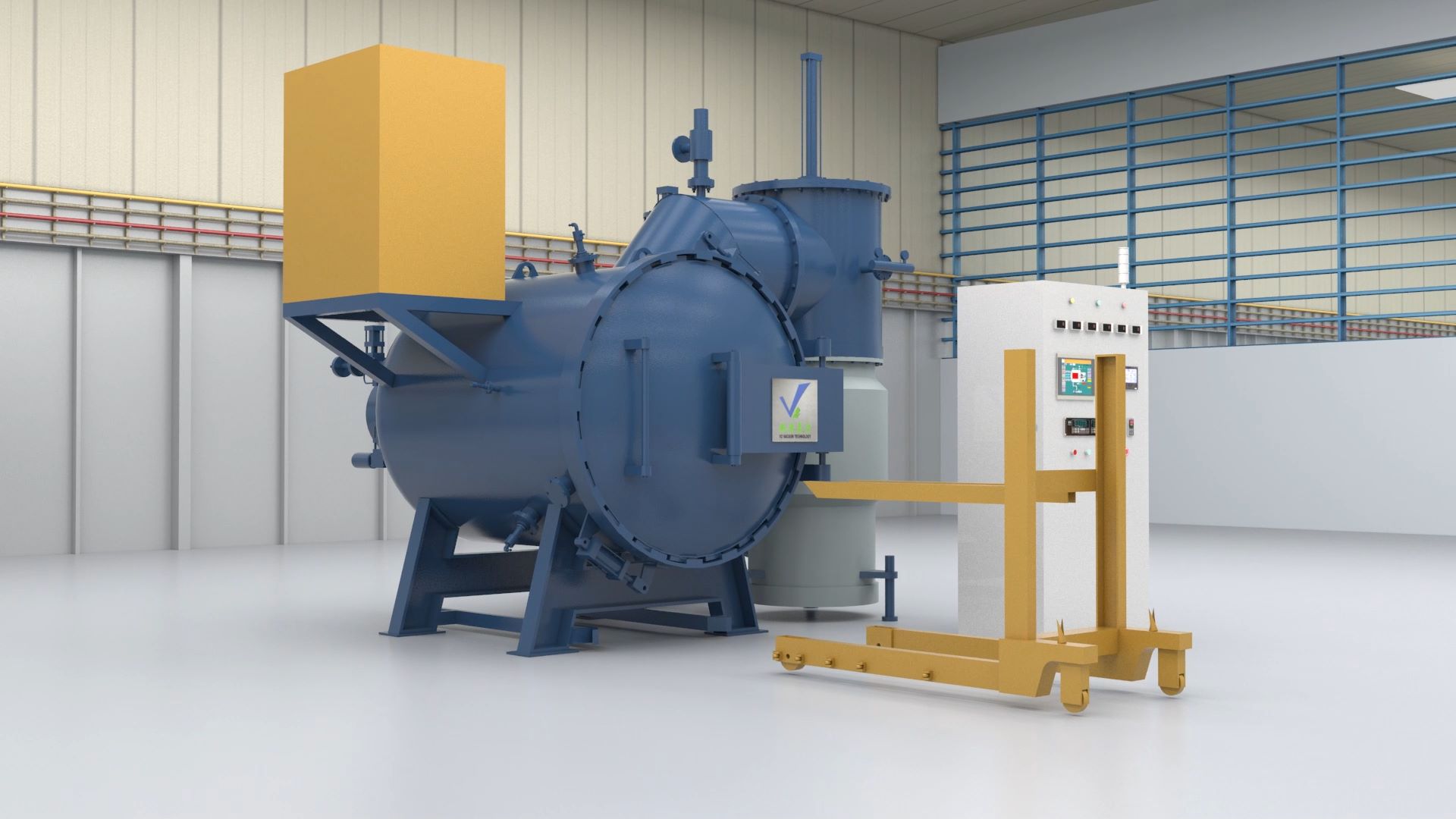

Vacuum Gas Quenching Furnace for Heat Treatment

-

Double Chamber Vacuum Furnace for Oil and Gas Quenching

-

Vacuum Tempering Furnace for Heat Treatment

-

Vacuum Annealing Furnace Heat Treatment

-

High Temperature Vacuum Soldering Furnace for Brazing Copper Alloys, Stainless Steel

Furnace for vacuum soldering of aluminum radiators

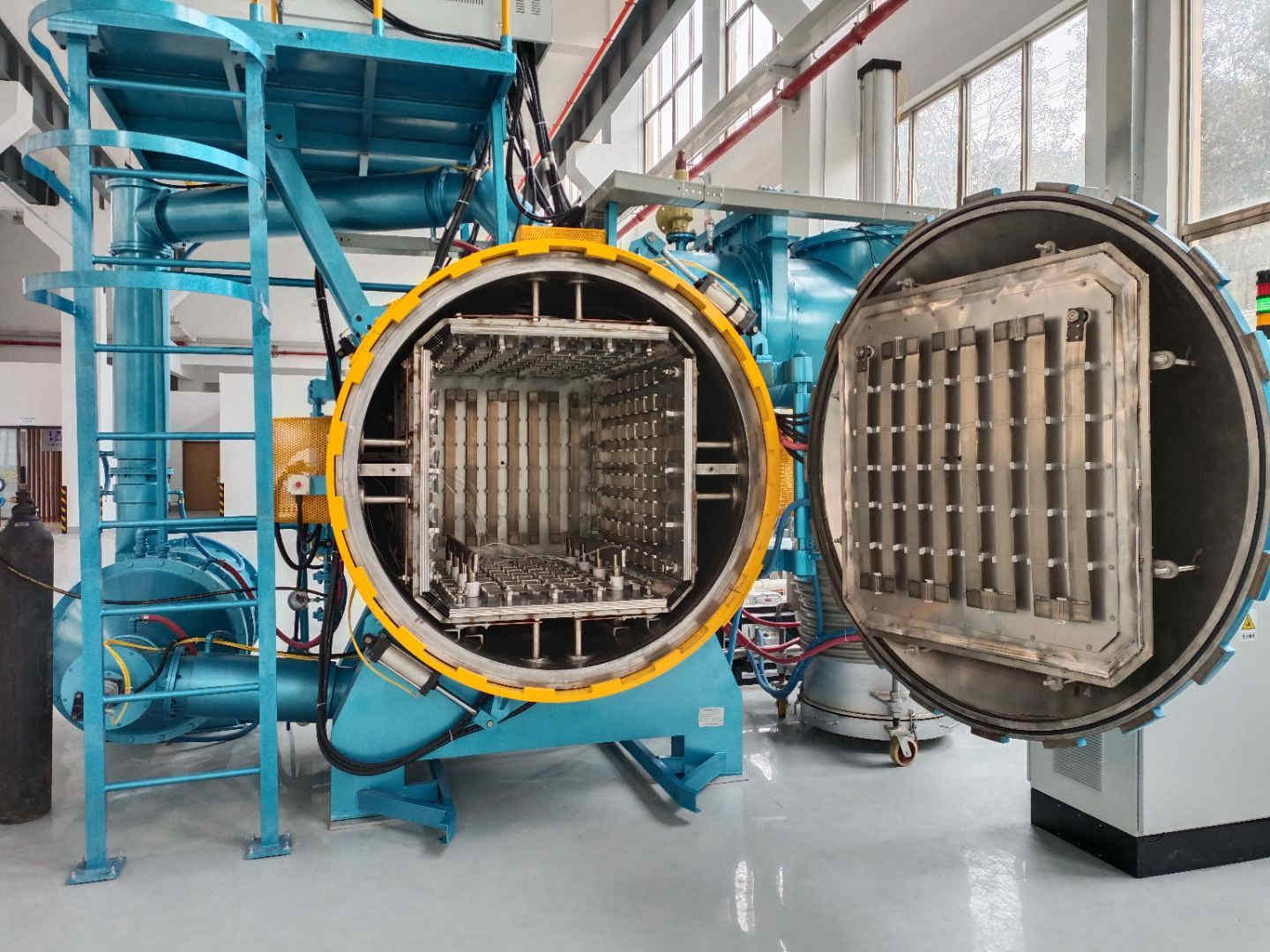

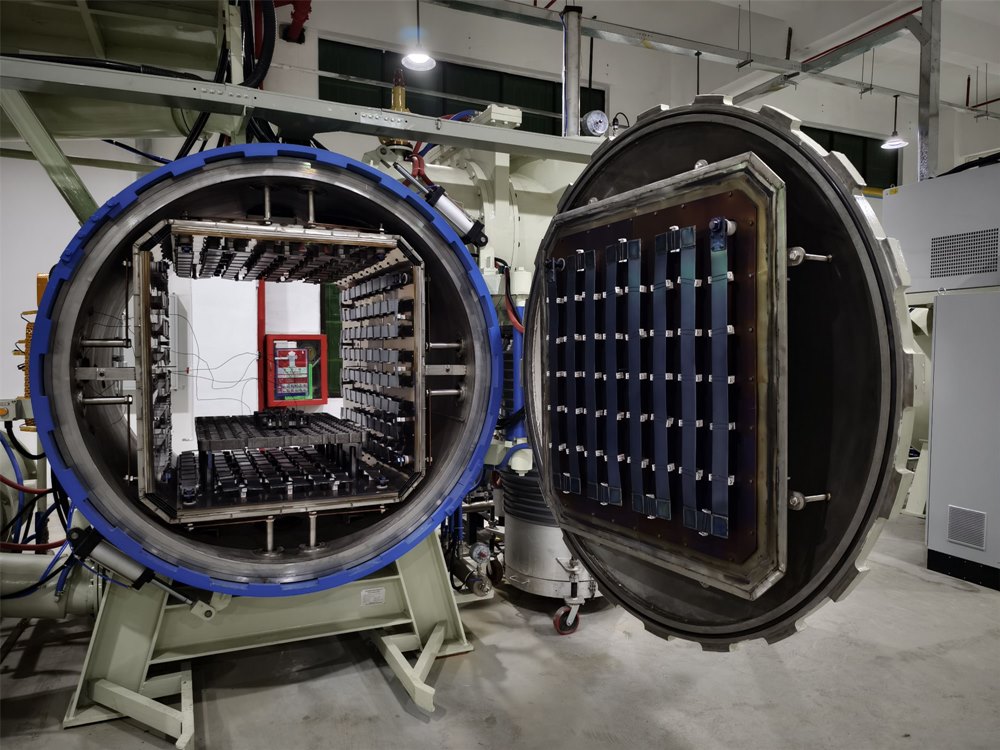

The vacuum aluminum brazing furnace is suitable for brazing aluminum products such as aluminum plate heat exchangers, automobile radiators, automobile air conditioner evaporators, capacitors, radar network antennas and waveguide tubes. It has properties such as no pollution, no flux, no porosity, no slag, energy saving, etc.

Adopting internal circulation cooling mode, heating and cooling are separated, and the all-metal screen is used to preserve heat, which ensures the high degree of vacuum required for soldering workpieces. The heating element is made of nickel-chromium alloy, heating uses multi-zone temperature control, each zone can be controlled and disassembled separately, which can ensure good temperature uniformity in the temperature zone. The reflective screen and frame are made of high quality SS304 material.

Description

marker

use:

Furnace for vacuum soldering of aluminum radiators

Specification

| model | size (mm) | Load capacity (Kg) | Heating element | Maximum temperature (℃) | Temperature Uniformity (±℃) | Maximum vacuum (Pa) |

| VTB-335 | 300×300×450 | 100 | Ni-Cr | 750 | 3 | 6×10-4 |

| VTB-446 | 400×400×600 | 200 | ||||

| VTB-557 | 500×500×700 | 300 | ||||

| VTB-669 | 600×600×900 | 500 | ||||

| VTB-8812 | 800×800×1200 | 1000 | ||||

| VTB-9920 | 900×900×2000 | 1500 | ||||

| VTB-3.6L | 1100×1100×3600 | 2000 |

Furnace for vacuum soldering of aluminum radiators

Vacuum aluminum brazing furnaces are considered flux-free vacuum aluminum brazing furnaces because no flux is used to remove oxides. A vacuum pump pumps air out of the furnace, thereby reducing the oxygen content in the PPM in the vacuum chamber of the aluminum brazing furnace, which prevents the formation of oxides. Magnesium is used as an absorbent in vacuum aluminum brazing furnaces to improve the cleanliness of the vacuum aluminum brazing furnace environment and facilitate the removal of oxides. The advantage of vacuum aluminum brazing furnaces over other metal joining methods is that vacuum aluminum brazing furnaces do not melt the base metal of the joint, so vacuum aluminum brazing furnaces allow for more precise control of tolerances. Industrial applications of vacuum aluminum soldering furnaces range from semiconductors to aerospace. Applications that are well suited to vacuum aluminum brazing furnaces include: parts with thin to thick cross sections with subsurface joints or jointed assemblies; denied access; nodes with a large number of connections

7 advantages of a vacuum furnace for aluminum soldering!

VTB soldering ovens offer a number of advantages that other processes do not offer. Contains.

1. Provides clean connections without the need for additional finishing and cleaning

2. Compared to partial joining processes, the entire assembly is heated and cooled evenly, which minimizes part deformation 3. Assemblies with large surface area and numerous joints can be successfully processed in a vacuum aluminum brazing oven

4. Provides highly repeatable results as each load controls key oven parameters, i.e. vacuum and temperature.

5. Forms a continuous sealed connection

6. Ideal for working with corrosive or oxide-sensitive materials as the use of corrosive fluxes is eliminated